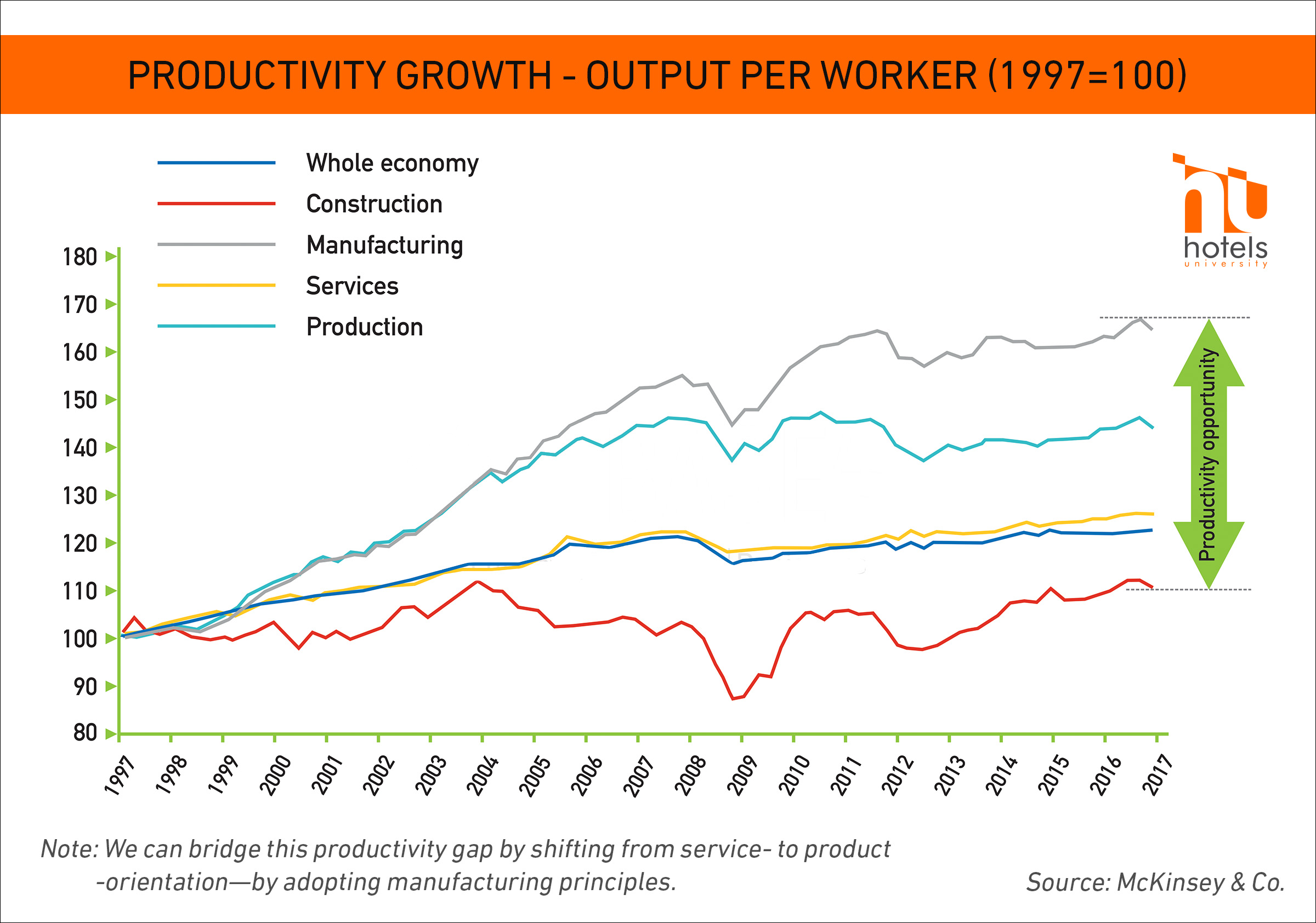

Over the past two decades, the construction sector’s annual productivity growth has merely increased 1% on average compared to 3.6% for the manufacturing industry.1 An efficiency boost has become crucial for this trillion-dollar industry in this day and age.

Good news is, modular construction is quickly emerging as a winning method to build. So, every developer should understand and make the most of it.

This newsletter introduces a concept called design for manufacture and assembly—aka DfMA. This method is effective because it takes a product-centric approach as opposed to AEC’s service-based mindset.

Design for Manufacture and Assembly

Most automobiles and consumer goods that you use are made using DfMA. DfMA is catching on in modern methods of construction (MMC), thanks to modular construction’s assembly-line approach. But what is it, after all?

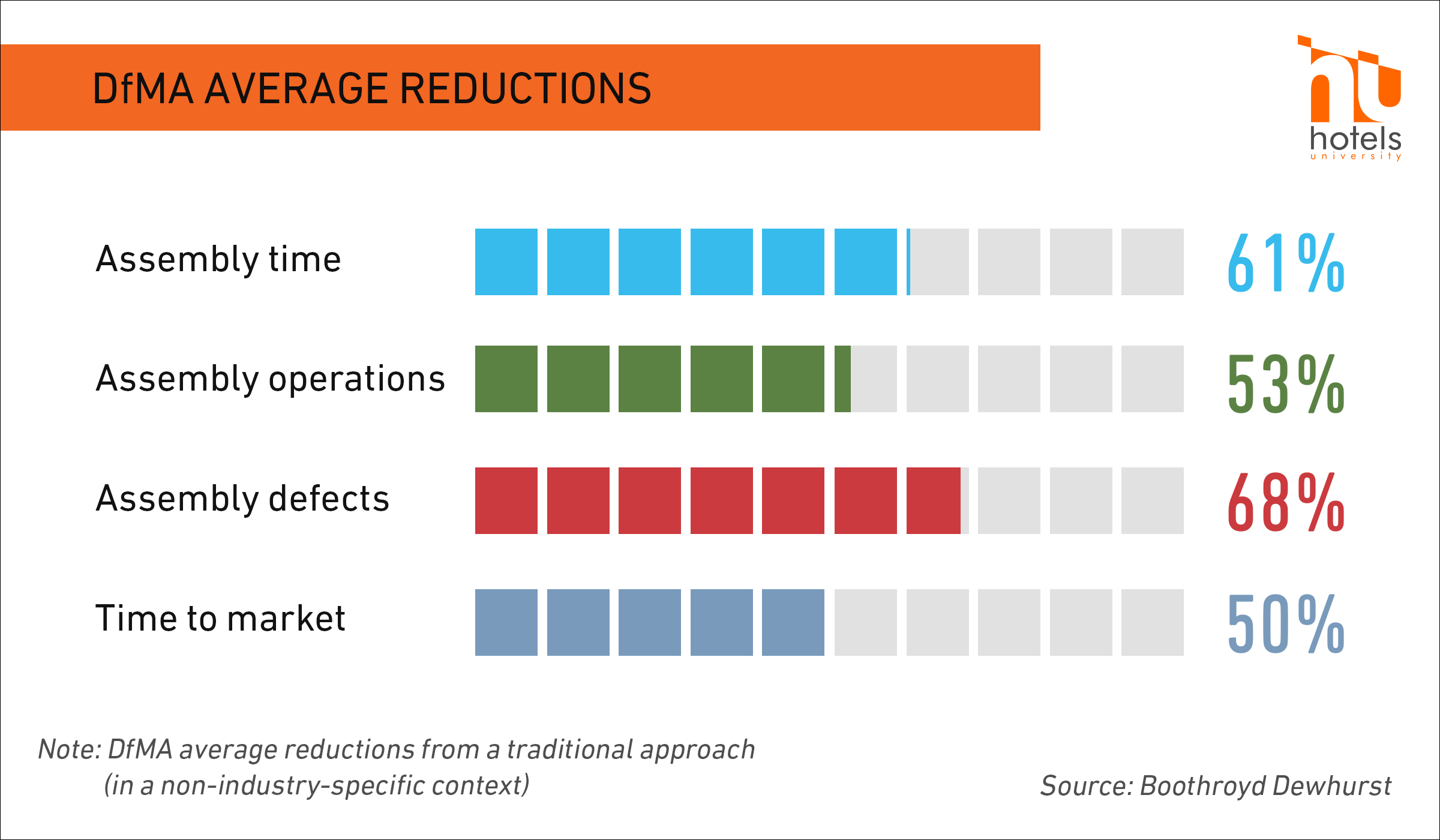

Simply put, DfMA is a design method that simplifies production and assembly of factory-manufactured goods—ultimately reducing time, waste, cost, and labor, while increasing quality and efficiency.

This methodology combines two concepts:

- Design for Manufacture: DFM deals with choosing the most cost-effective materials and processes to simplify operations.2

- Design for Assembly: DFA is a product designing approach that ensures smooth and easy assembly of products—while reducing assembly costs and minimizing operations.2

An Example

- Imagine a structural wood panel (such as OSB) being used at a traditional jobsite. A sub contractor will need to manually measure and cut these panels into specific blocks and parts—right at the jobsite—and the remainder goes to waste.

- Conversely in manufactured construction, material usage is planned right from the design stage. The designer creates Revit models of these boards with a cut-list generated for each module, which is used to pre-cut the boards in exact dimensions.

- These pre-cut boards are batched together, and each batch corresponding to a specific module is sent to the right place in a modular factory for assembly.3

- Thus, simplifying the process and planning materials right from the design stage help reduce waste and leave little room for errors.

DfMA in Construction

For an industry as fragmented and antiquated as construction, a streamlined methodology is a welcome approach. DfMA can be achieved through BIM, which is already a powerful medium to collaborate, manage, and visualize a project.

BIM’s involvement also means that all project parties—including the architect, engineer, modular manufacturer, contractor, and developer—know the exact details of the project.

It’s best to adopt DfMA (and hence, modular construction) early in the design stage—as this article explores in detail.

Highlights

- Better speed: Prefabricated components reduce on-site work and coordination, resulting in fewer roadblocks.

- Higher reliability: Fewer components and simplified operations bring down project complications.

- Improved safety: A factory-controlled environment reduces work-related hazards compared to a traditional construction site.

- Lower assembly cost: Optimized labor, material, and coordination save time and money.

- Reduced waste: Smartly chosen materials and precise quantities help reduce construction waste.

- A seamless transition and faster turnaround time

- Superior quality and viability

If you have follow-up questions regarding DfMA or modular construction—or simply want to say hi—feel free to reply to this email.

And if you’re considering a new project, fill out this form—we’ll be in touch!

Thank you,

Blair Hildahl

Base4 Principal

608.304.5228

Blair@hotelsuniversity.com

![]()

Sources:

• Reinventing Construction: A Route to Higher Productivity: A report by McKinsey & Company

• https://www.designingbuildings.co.uk/wiki/Design_for_Manufacture_and_Assembly_(DfMA)

• http://www.modularize.co.uk/the-true-meaning-of-dfma/

Leave A Comment