So, you want to dive into offsite, prefabricated, and modular, but your project doesn’t seem to fit. This article is dedicated to you—and how panelized construction can be the prefab solution to match your project’s unique spaces and size requirements.

As you can tell from our previous columns on DfMA for multifamily, volumetric modular construction, and bathroom pods, you understand that Industrialized Construction is the solution to today’s construction gridlock. As a continuation of this series, today we explain the benefits of using different types of panels for your multifamily project.

What is a panelized construction?

Panelization is the process of manufacturing prefabricated exterior and interior wall, floor, and roof assemblies under controlled environmental conditions using light wood or light-gauge metal framing. The panels are prepared using cutting-edge automation, assembled according to the design specifications, and then packaged for transportation.

- Flat-panel units are built in a factory and later transported to the site to be assembled into a three-dimensional structure or to fit within an existing structure.

- The panels can be made of steel, timber construction materials, concrete, or masonry.

- Systems can include walls, floors, and roof panels to create the complete structural shell.

Wall Panel Systems

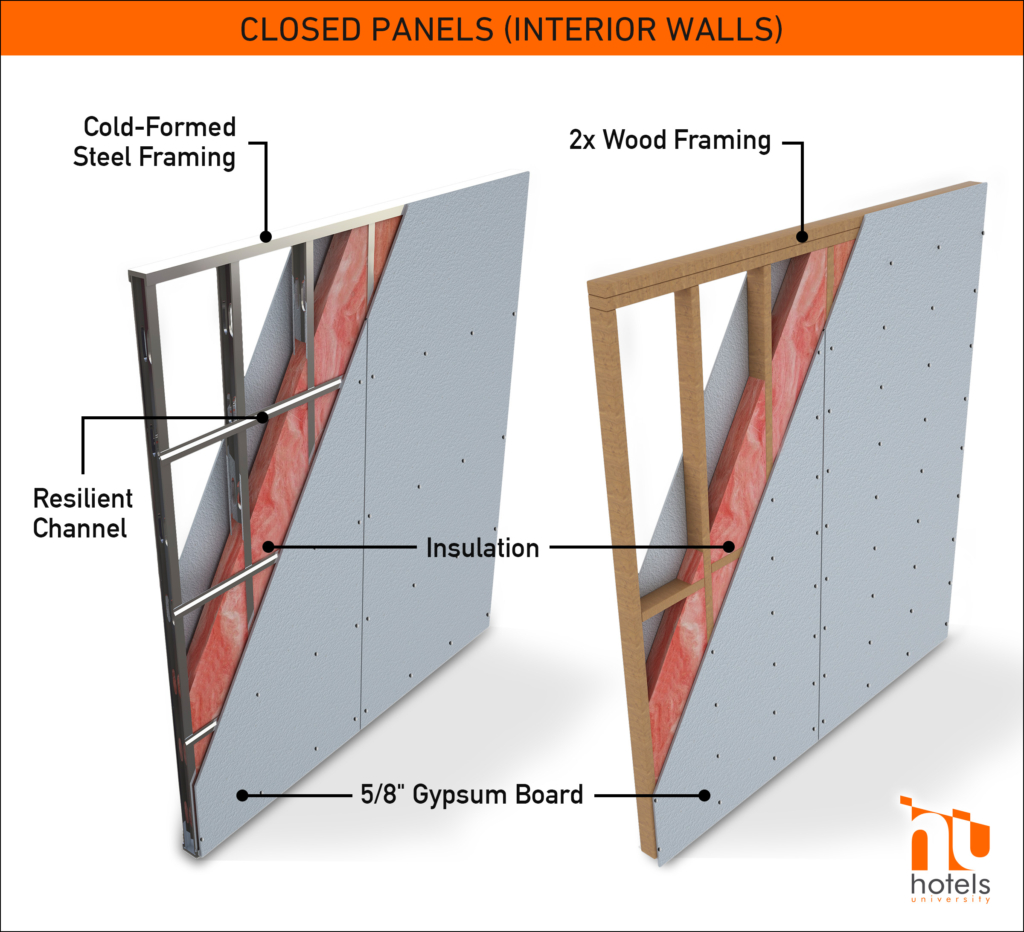

Wall panels can be factory-built to different levels of completion from just the structure (Open Panel) to completely finished (Closed Panel) with drywall, doors, windows, services, internal wall finishes, and external cladding—all factory installed.

Materials:

You can use the following materials to match the needs of your unique multifamily project. Similar materials used for wall panels also can be used for flooring and roof systems.

- Wood Framed Panels: Wood has long been the go-to framing choice for residential and commercial buildings—most often Type V and Type III construction—due to its cost and ease of assembly.

- Cold-Formed Steel Panels (CFS): These framing members are structurally sound and provide an alternative solution to typical block and plank construction. Load-bearing walls are panelized to allow for a quality exterior shell to be completed quickly and safely. This method of framing is ideal for 4-12 story buildings. Specializing in CFS, Framecad provides the roller equipment for CFS, enabling companies to make panels in their own factory, if desired.

- Structural insulated panels (SIPS) & Other Composite Systems: The board can be sheet metal, plywood, cement, and polyurethane foam and can be used for floors, walls, and roof systems. SIPs are manufactured under factory-controlled conditions and can be custom-designed for any project. They do not rely on internal studs for their structural performance.

Benefits:

- Saves Time and Money: A recent study showed that using wall panels reduced framing labor time by 71% for a 2600 square-foot house.

- Quick Assembly: With precision design and no weather delays, panelization means a 37% faster build than traditional stick-frame construction and produces a superior quality finished product.

- Precision Fit: The precision of automated production produces elements with precise dimensions, increased quality, consistent fit, and consequently, good energy performance.

- Easy Coordination: The coordination process between disciplines is smoother since a Closed Panel System means all MEP connections are already installed in the wall.

- Quality Construction: When panels are assembled in a controlled environment it requires fewer employees on site, lowers the chance of job site burglary, increases QC checks, and allows for volume purchasing.

- Environmentally Friendly: Precision factory assembly means reduced construction material waste, less job site disturbance, and easier site clean-up.

- Flexible Design: With computer-assisted design (CAD-REVIT) programs, designers and engineers can turn just about any idea into a working blueprint.

Next week, I will continue the Industrialized Construction for multifamily series with a discussion of what are Sub-Assemblies & Components and how they can help with the construction process.

As an AEC futurist, I believe so much in the power of offsite, prefabrication, and modular construction that—together with the BASE4 team—we launched a master’s program dedicated to the topic. Check out Stonepile Construction College, where students enjoy an online and innovative higher education experience. Feel free to contact me if you have any questions.

Thank you,

Blair Hildahl

Blair@hotelsuniversity.com

608.304.5228

Leave A Comment