Practical Guide to Energy Savings for this Summer and Beyond

After reviewing the practical points about thermal insulation from last week, let’s jump to real-world solutions that you can implement for your next hotel.

Design Considerations

An expert design team can design your hotel to conserve energy over time. Certain building materials, insulation practices, and design considerations may reduce your hotel’s energy consumption when understood through the lens of the code requirements and geographical considerations.

Utilize Wood Over Steel

- For exterior walls and roofs, framing material can significantly impact thermal bridging (i.e., the flow of heat through the building materials), which should be as low as possible.

- Wood frames perform far better than metal frames because of the higher heat resistance of wood and increased thermal bridging in steel.

- As illustrated below, for an R-19 batt insulation, effective R-value of the wall assembly becomes 7.1 for steel and 16 for wood studs.

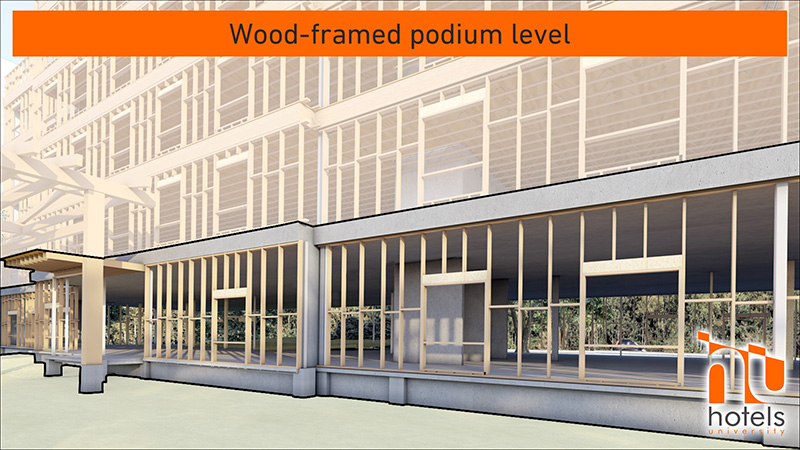

- With wood maintaining a higher effective R-value, a podium level (made of concrete, as shown below) framed with wood studs helps optimize energy efficiency.

According to the Code

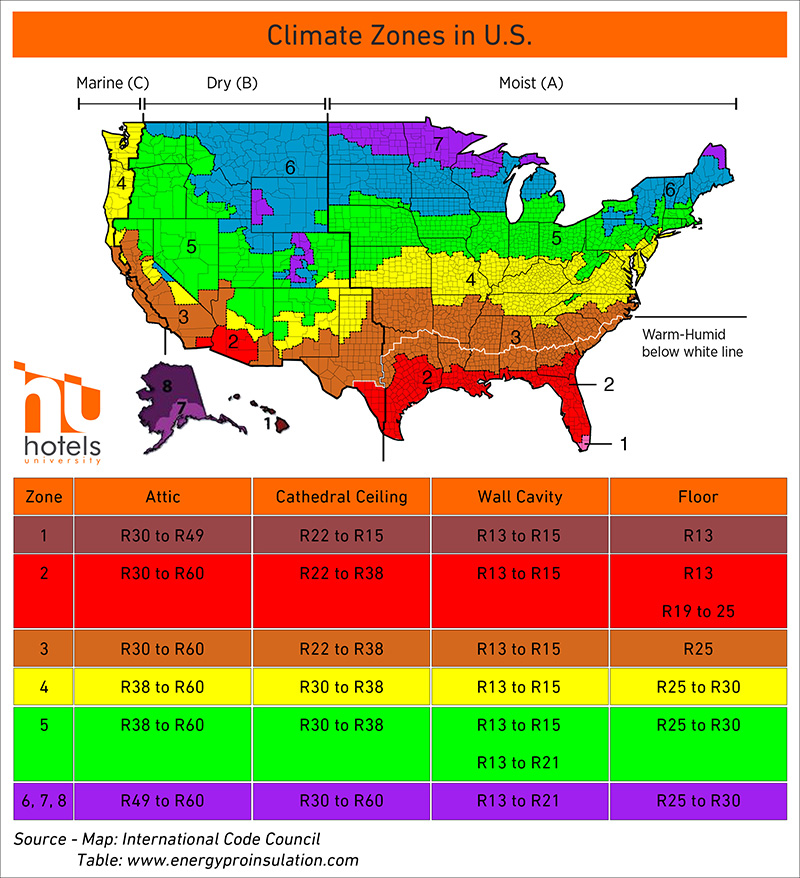

- The International Energy Conservation Code (IECC) specifies minimum R-value requirements for the thermal insulation of the envelope (i.e., the physical separator between conditioned and unconditioned areas of a building). This varies greatly based on the project’s construction type, geographical location and climate zone.

- The graphic below shows the U.S. climate zones with their respective minimum R-ratings.

- The IECC recognizes wood’s advantage over metal in heat resistance. While both wood (in climate zones 1-5 with some exceptions) and metal framed buildings require cavity insulation, the code mandates an additional continuous insulation applied to one face of the above-grade metal-framed walls. According to the IECC, wood-frame walls with an R-20 rating are the only available options that do not require continuous insulation for above-grade walls.

- Continuous insulation can be included in energy compliance programs like COMCheck to increase the efficiency of the envelope.

Watch Out for Weak Spots

- Doors, windows, areas around PTACs, construction joints and connections—among others—are prone to energy leaks.

- Knowing common R-values of such areas helps in choosing more energy efficient products.

- An Energy Star-rated window would hold an average R-value of 3. Some companies now produce energy efficient windows with up to R-5. 1

- Superior to solid wooden doors, most fiberglass and steel-clad entry doors without a window hold R-value of 5 to 6. To put it into perspective, a 1.5-inch thick steel door with foam insulation core holds over five times the insulating value of a same sized solid wooden door. 2

Optimal Thermal Insulation Practices:

- Guard the Windows: Inefficient windows waste 25-35% of a building’s energy. 3

- Consider high-performance windows and insulate with energy-efficient shades.

- Installing window films can highly increase energy savings. They come in varying shades and opacities and fit any shapes and sizes.

- Protect the Doors: The door is another energy leaking spot.

- Regularly used revolving doors can save you big. Two such doors in a hotel can annually save $7,500 worth of gas used in heating and cooling.4

- Regular doors can be insulated using certain types of foam, vinyl, metal, silicon, and tape, among other materials—a process also known as weather-stripping.

- Choose Quality Materials: Use high-quality insulation materials with higher R-ratings for long-term savings. Again, the climate zone and geographical location of your hotel will likely determine the optimal choice of insulation.

- Find Reputable Firms for Installation: Have professionals take care of insulations per manufacturer’s installation guidelines. This ensures that the insulation extends as needed across areas vulnerable to greatest energy losses, such as along construction joints & connections, pipes, conduits, chimneys.

- Use Cool Roofs: With summer approaching, hoteliers in warmer zones spend more on cooling. Read how cool roofs can help!

- Seal any extra gaps using caulk.

- Integrate other ways to reduce energy consumption, including different choices for electric, HVAC, water, and lighting systems. Check out our earlier article on utility savings.

These ideas are only a brief overview of a very complex topic in building design today. It is important to consider a cost/benefit analysis when choosing the proper design choices for the best thermal insulation of your hotel. Additionally, COMcheck is available through the Department of Energy, providing access to software to assist in optimal design ideas to achieve both energy code compliance and cost savings.

Due to the quality of materials, costs of insulation vary—and in some cases—are much higher. Given the many choices and options, having a team ready to answer questions is vital to harness these energy-saving ideas while still staying within budget.

Please reach out if you have questions about thermal insulation for your next hotel!

Thank you,

Blair Hildahl

- https://www.architectmagazine.com/technology/products/the-latest-highly-insulating-windows-are-almost-as-efficient-as-a-wall_o

- https://www.energy.gov/energysaver/design/windows-doors-and-skylights/doors

- https://lodgingmagazine.com/how-window-film-can-help-hotels-become-more-energy-efficient/

- https://www.buildings.com/article-details/articleid/15979/title/automatic-doors-vs-revolving-doors/viewall/true

Recent Comments