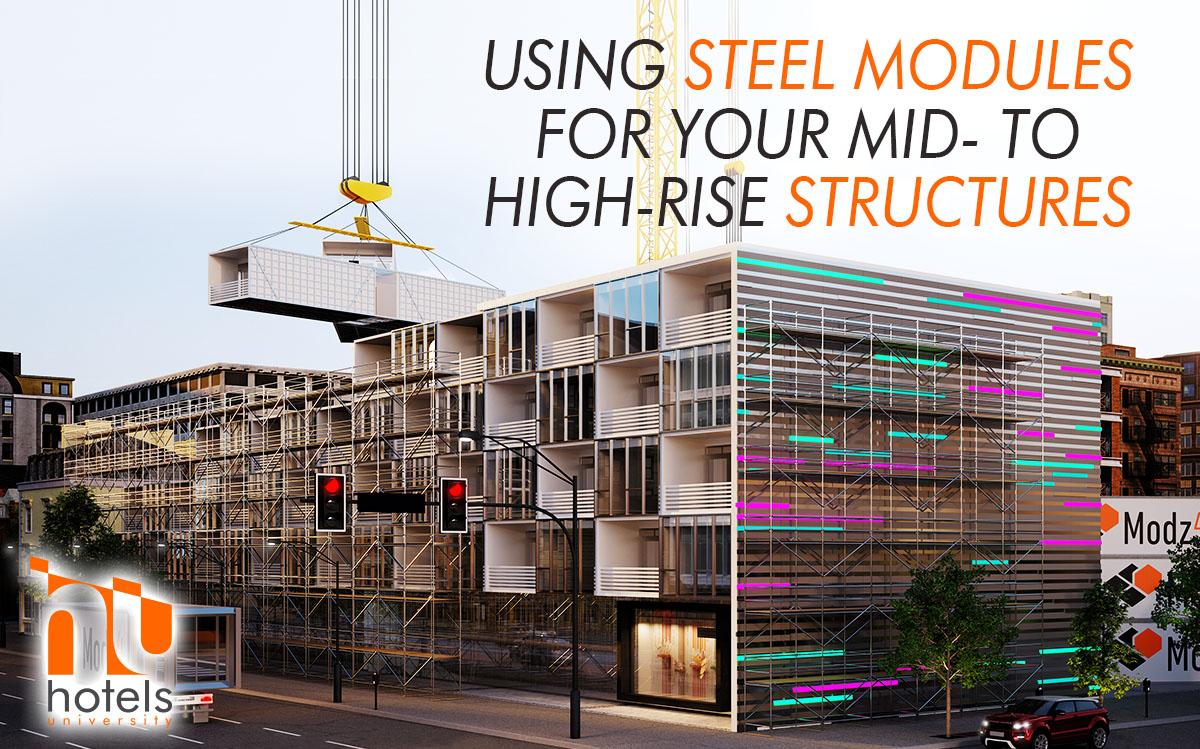

Using Steel Modules for Your Mid- to High-Rise Structures

If you’re planning a mid- or high-rise construction, this piece is for you.

Modular construction, as you know, is picking up everywhere. But what’s the catch? Is it safe for a high-rise? Should you consider prefab over stick-built? You may have had these questions for a long time. So today, I compile them for you to make an informed decision.

This article talks about steel frame construction for mid- to high-rise structures, which may be useful for multi-family, hospitality, and other high-rise commercial spaces. For more information about wood modular building, check out our full series here.

How high can I build with modular?

What does a standard, full steel modular box look like?

What are size constraints and workarounds for steel modules?

What type of quality of finishes should I expect from a modular project?

I have projects in urban, rural, and specialized locations. How does it change my modular plans?

Is modular safe for earthquake-prone areas?

How far do modular companies ship from their plant to my site?

My projects are spread across multiple regions. Do I have to choose new teams for each?

Who is accountable for quality and deadlines? Who coordinates with the manufacturer?

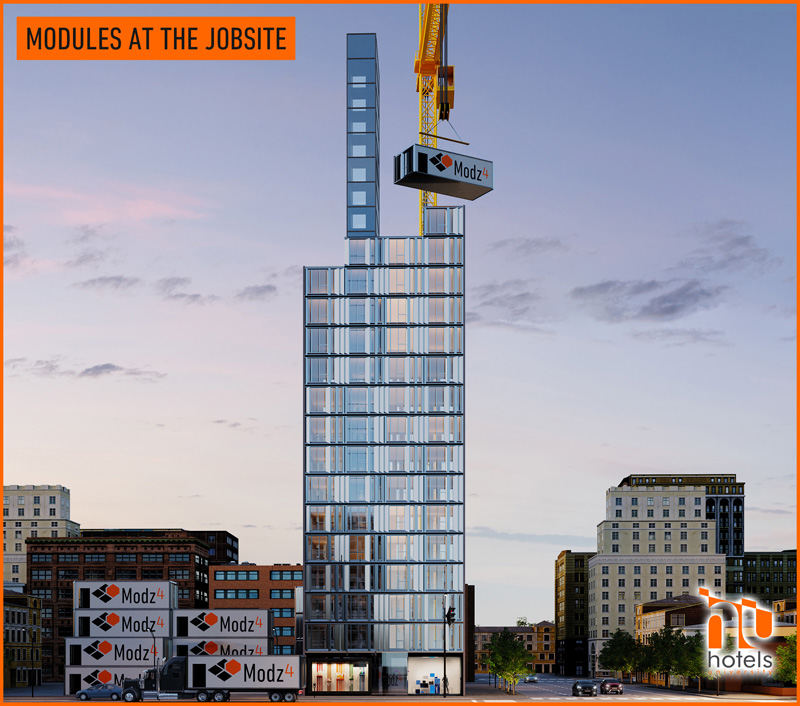

What do modular boxes look like when they arrive at the site?

What happens once the modular boxes arrive on site?

Can I place modules directly on the ground floor slab?

How many modular boxes can I set in a day?

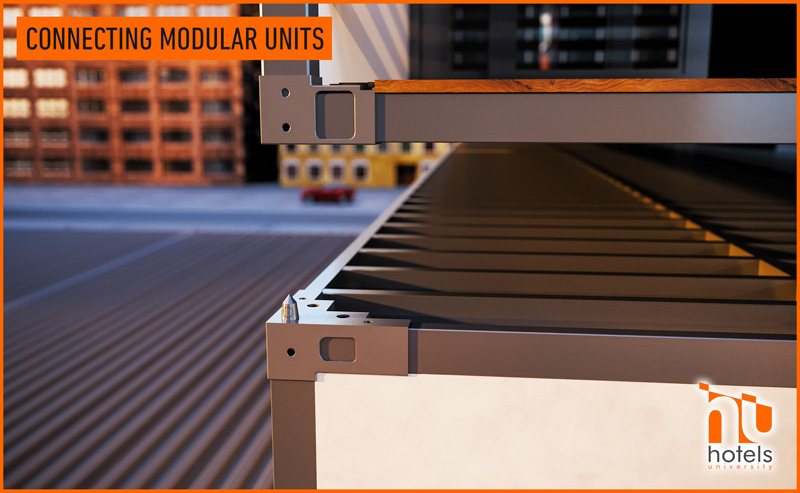

How do modules connect?

How are local inspections handled?

How high can I build with modular?

- Currently, some modular buildings are crossing 400 feet in height with 40+ stories in the UK and China.

- In the U.S., some modular buildings are breaking records now, going higher than the famed 25-story AC Hotel by Marriott in New York.

- From a low-rise to a high-rise, modular can be the most efficient and advanced way to build if the logistics of off-site construction match your project needs.

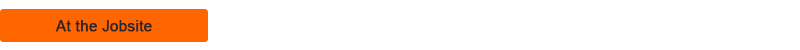

What does a standard, full steel modular box look like?

- A steel-framed modular box contains one guestroom unit with an optional corridor space.

- Unlike wood modular boxes—which come with two guestroom units separated by corridor space—steel modules have just one such unit due to the weight of steel.

- Each module’s MEP connections are made through the corridor, which are attached later onsite.

- Just like wood modules, manufacturers design and equip steel guestroom units with all necessary furniture and finishes—everything down to the bed mattress. However, the corridor is left unfinished with open stud walls for onsite MEP work.

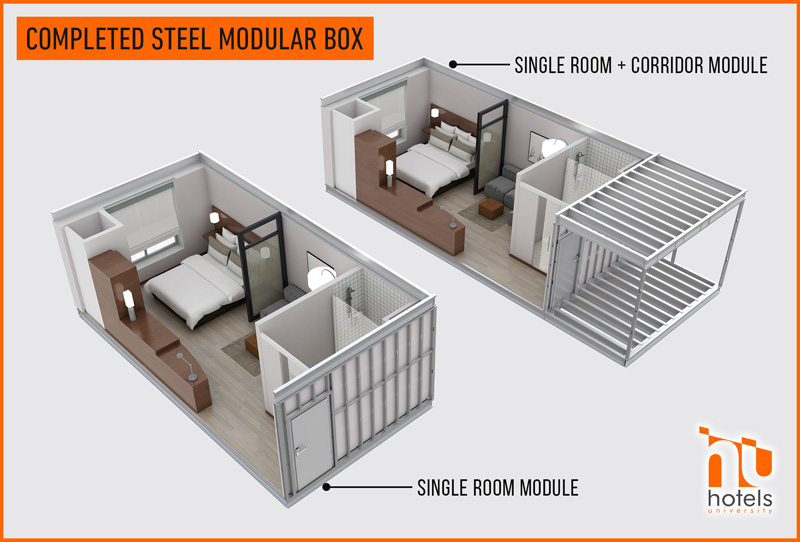

What are size constraints and workarounds for steel modules?

- Modular boxes have a strict size limitation. Due to shipping and weight constraints, each module cannot be more than 14 to 16 feet wide and 11 feet high. Up to 40 ft long boxes are more practical. 1

- For larger room-units, multiple partially open-sided modules can be set side-by-side to achieve the desired area.

- If your project requires high ceilings (more than 11 feet), modular alone won’t work—but architects and designers are successfully building time-efficient, hybrid projects where living spaces such as lobby and back-of-house are built traditionally while guestrooms are modular.

What type of quality of finishes should I expect from a modular project?

- Modules are produced in a controlled environment by specialized members for specific trades.

- Each person on the assembly line consistently delivers high-quality products in accordance with developed standards.

- Only the corridors and lobby require finishing work at the project site.

- As a result, modules have a higher level of precision and consistency than you will see with a traditionally built project.

- See the factory of Z Modular below. It is a prominent steel modular manufacturer using high-quality steel and finishes. Hundreds of modular boxes are simultaneously produced at the expansive manufacturing unit in Birmingham, Alabama.

Steel modules on assembly line at the Z Modular factory

I have projects in urban, rural, and specialized locations. How does it change my modular plans?

- Building mid-to high-rise in urban locations call for a highly customized modular plan—including dimensions of modular boxes.

- Urban areas need a different design approach —so be sure to have experienced architecture firms like Base4 on board that specializes in spatial design.

- Rural and suburban locations typically must match design standards of the local codes. While standard modular designs might work, you want your design team to do thorough code reviews to guide the decision-making process.

- For specialized areas, such as airports or universities, standard steel boxes may work. Discuss with your manufacturing and design teams what is the preferred design for your project requirements.

- No matter the geographical location, high-rise builds might require the module specifications to change for every floor.

Is modular safe for earthquake-prone areas?

- Steel modular construction can be safe for areas with high seismic activity if structural engineering is performed correctly.

- For the building’s stability against external forces such as wind and earthquake, structural load bearing is crucial—expert engineering firms such as Base4 have years of experience designing structures to withhold seismic forces.

- Moreover, modular boxes are also designed differently for each floor, since lower stories need to withstand higher load compared to upper floors. Each module has a number based on its location in the building that no other unit can replace.

How far do modular companies ship from their plant to my site?

- Most modular building boxes are shipped from within a 500-mile radius of the construction site, although shipping distance is determined by the complexity of the project.

- Many prominent manufacturers also ship steel modular units from overseas via vessels—from as far as China and Poland.

- Shipping distance is often driven by cost considerations, so there is a certain distance that may make shipping unfeasible.

- But make sure first to discuss with your modular manufacturer—some companies will go farther when it makes sense for the project.

My projects are spread across multiple regions. Do I have to choose new teams for each?

- Normally, as long as your modular production factory is in a 500-mile radius, you can use the same teams on multiple projects.

- However, for the actual hotel design, your architects and engineers of record need to have licensure to practice in the state of your project. As noted previously, your design team’s relationships with local authorities go a long way.

- Specialized and experienced hotel design firms like Base4 have extensive reach in all 50 states, making your move to modular much easier. Our AEC project managers maintain smooth coordination between your modular partners, local authorities, and onsite contractors.

Who is accountable for quality and deadlines? Who coordinates with the manufacturer?

- The modular manufacturer directs the timelines on the module production and delivery. They also handle shop drawings and strategize the delivery, storage, and craning logistics.

- Your AEC team designs, engineers, and coordinates the bigger picture items, including structural components, foundation, lobby areas, corridors, MEP connections, and overall finalization of the project after the modules are delivered.

- All FF&E must be delivered at the modular factory before it starts production.

- Just as with wood modular construction, proper planning is crucial since FF&E deliveries can take significant time, and late deliveries may hamper the project schedule.

What do modular boxes look like when they arrive at the site?

- Delivered module boxes are assembled as large volumetric components, wrapped in plastic for temporary protection from inclement weather and damage.

- The modules truck to the site, as shown below:

What happens once the modular boxes arrive on site?

- The trucks arriving on site unload each unit and set it on cribbing, to free the trucks and avoid vehicle jamming at the site. Manufacturers may also provide storage space near jobsite if needed.

- The crane then lifts each unit from the cribbing and places it on either the already constructed first floor podium or a crawlspace.

- The construction crew makes final installations of electrical, plumbing, mechanical, and structural connections, generally in the corridor.

- To avoid any damage at this point of construction, every unit is locked, and on-site staff are not allowed in the room-units.

Can I place modules directly on the ground floor slab?

- Typically, modular boxes are placed either on a podium or over a crawlspace.

- This configuration allows access to the bottom of the units after they are set.

- When stacking on a traditionally framed ground floor steel or concrete podium structure, the modular units start at the second floor rather than directly on a ground floor slab.

How many modular boxes can I set in a day?

- This is heavily project- and weather-dependent.

- Ideally, modular companies aim to set 12 boxes per day on a 4-story project.

- Since steel buildings are heavier than their wood counterpart, they require more sophisticated and specialized connection mechanisms. Some manufacturers use their own patented product—such as Vector Bloc by Z Modular—more general options are also available on the market.

- Connection systems are sophisticated mechanisms that ensure uniform load bearing and give buildings structural strength. There are several topologies of connections engineered per project basis.

How are local inspections handled?

- The modular approach reduces the number of local inspections from a traditional project.

- Inspections of the modular boxes must be completed at the factory when inside access and amendments are still possible.

- Most modular companies will handle this as part of their fabrication contract and will have the modular boxes stamped for the specific state approval to which they are being delivered.

- Once a module arrives on site, local inspectors have no jurisdiction over the actual units themselves. However, the inspectors will still be responsible for many aspects of a project—such as ground floor areas and corridors, among others.

- Educating local inspectors about jurisdiction authority over the room-units is important.

If you’re considering modular but not sure whether to choose wood or steel framing, check out my last article about wood prefab construction—or better yet, reach me with your queries! Let’s discuss whether modular is right for you. And if it is, what are your next steps.

Next week, I conclude my Introduction to Modular series with some more quick tips and summary.

Make sure to sign up for our Modz4 newsletters for continued free modular education!

Thank you,

Blair Hildahl

Recent Comments