Hotel Laundry: Common Issues & Major Expenses

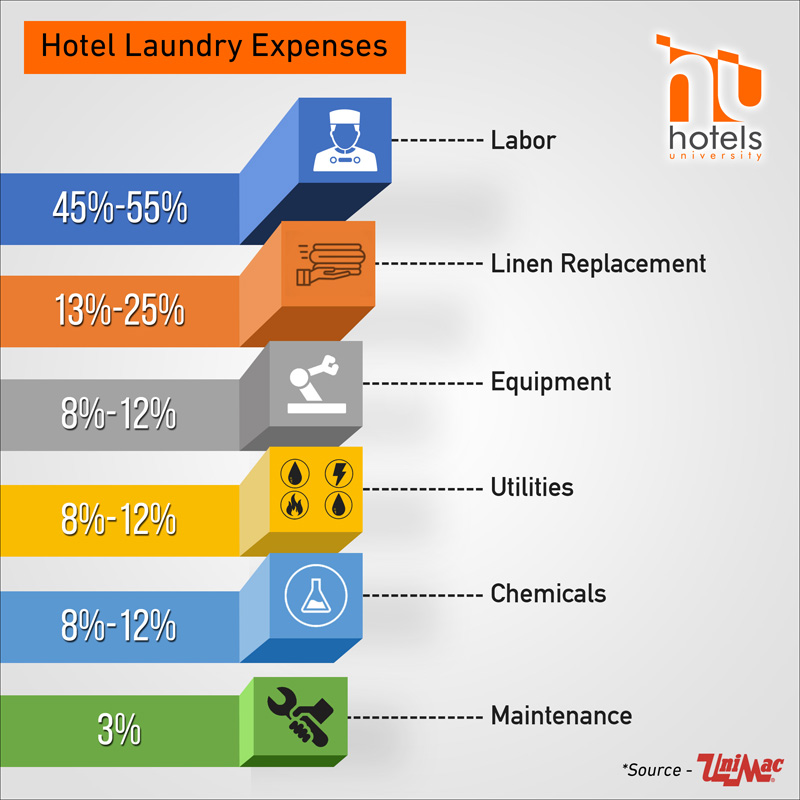

In my previous newsletter, I discussed the basics of designing a hotel laundry area. Today, I present some important considerations for creating a well-maintained laundry system. I also discuss approximate hotel laundry expenses according to various hotel laundry needs.

LAUNDRY ROOM PLACEMENT:

- High extraction hard mount washers tend to vibrate, so these units should be installed on the ground floor and bolted to a 12-inch concrete slab, if possible.

- During the initial conceptual space planning, you need to think through laundry travel routes from the guestrooms, meeting areas, and amenity spaces to the laundry room. Avoiding interaction between hotel laundry loads and guests is critical. Therefore, a rear opening elevator with direct laundry room access is an important aspect of your ground floor design considerations.

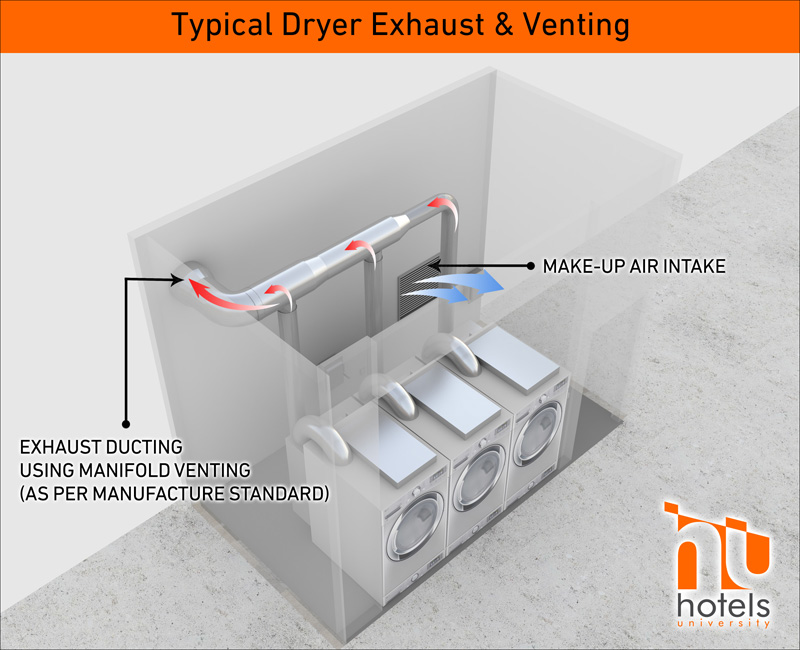

- Dryer units should always be installed on an outside wall when possible so that make-up air and venting lengths can be kept to a minimum.

COMMON ISSUES:

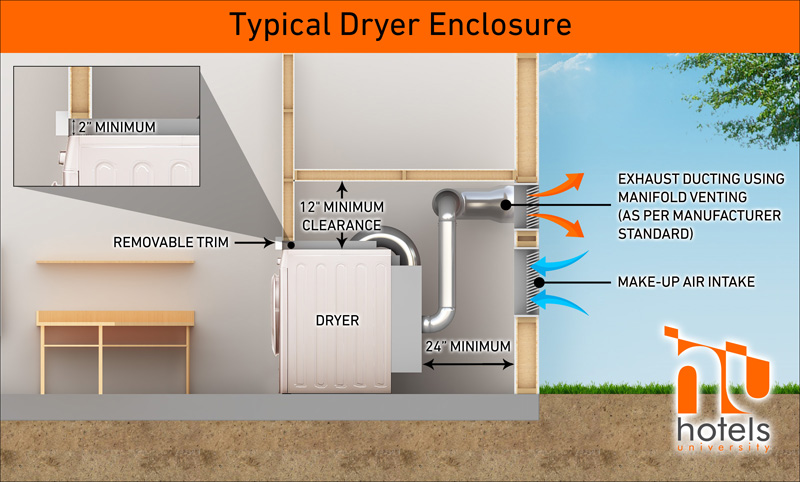

- Undersized Laundry Rooms – Efficiently running laundry operations require space for housekeeping staff to work and maneuver carts. Developers who are not operating the hotel often mistakenly undersize these spaces to prioritize front-of-house space for guests. Dryers should also have a minimum of 2 feet (3′ preferred) clearance behind equipment to aid in maintenance.

- Undersized Equipment – Similar to undersized rooms, if developers are not familiar with BOH (back-of-house) laundry operations, they may undersize equipment as part of a value engineering exercise. Having equipment that cannot keep up with laundering demands leads to extended housekeeping hours.

- Door Access – Restricted door access is a common problem! For example, a typical 75-pound dryer will not fit through a standard 36-inch wide door. A larger 120-pound unit can be more than 46 inches wide. Designers must carefully think through door sizing and access to ensure units can be delivered to the space.

- Dryer Make-up Air – A typical tumble dryer uses forced air exhaust, which requires make-up air to replace vented air. A standard 75-pound dryer requires nearly 200 in2 of open access to fresh air. High-performance models require 250 in2 or more. These openings should not be located near venting grilles (see below) in order to avoid reintroduction. Owners should be cautious of ground clutter and snow which can obstruct these openings and dramatically reduce the performance of the equipment.

- Dryer Venting – Units must also be vented. Manufacturers recommend individual venting with one duct per unit to fresh air with a 14-foot maximum run. Although not preferred, manifold venting using a main collector duct may also be used. A laundry vendor should always be consulted for proper sizing.

- Dryer Enclosures & Noise – Manufacturers recommend enclosing tumble dryers in order to segregate the make-up air supply. This process also reduces the heat emissions in the laundry room by up to 80% and significantly cuts down on noise emissions which can be a common guest complaint for hotel rooms near laundry operations.

COST BREAKDOWN:

- Hard Mount Washers – Washers can be the most expensive part of a hotel laundry operation. Typically, these washers range from $10,000 to $13,000 per unit for a 65-pound unit. Larger 85-pound units may exceed $17,000.

- Dryers – A typical 75-pound fast-dry tumbler typically costs around $5,000 per unit. Larger 120-pound units may cost more than $8,000.

- Delivery & Installation – Although varying by geographic location, developers typically budget around $2,500 for installation of units.

If you’d like to discuss more hotel laundry area-design options, please contact our office.

Thank you,

Blair Hildahl

Blair@hotelsuniversity.com

608.304.5228

Recent Comments